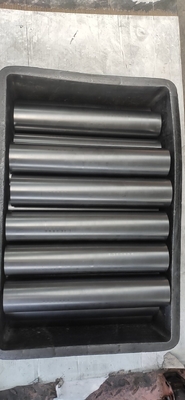

GR-150 Customization Low Density Graphite Anode Rod Extruded Graphite

Product Details:

| Place of Origin: | China |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Piece |

|---|---|

| Delivery Time: | Peak Season Lead Time: 6-12 months, Off Season Lead Time: 1-3 months |

| Payment Terms: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment, Money Gram |

|

Detail Information |

|||

| Model NO.: | GR-150 | Grade: | Industrial Grade |

|---|---|---|---|

| Forming Way: | Extruded Graphite | Crystal Morphology: | Flake Graphite |

| Composition: | 100% Carbon | Transport Package: | By Ply-Wood |

| Specification: | 20-75mm | Trademark: | DC |

| Origin: | Beijing, China | HS Code: | 2701121000 |

| Supply Ability: | 150PCS Per Day | Customization: | Available |

| Density: | 1.6 | Type: | Graphite Rod |

Product Description

China manufacturer low density graphite anode rod:

Graphite rods are often used for following:

1. Refractory material:

Widely used in the metallurgical industry.

2. Conducting material:

In the electronics industry, widely used for graphite electrode, brush,, etc

3. Wear-resisting material and lubricant:

Use graphite as wear-resisting and lubrication materials, can be 100m/s speed sliding in - 200 ~ 2000 °C temperature range, no or less lubricanting oil.

4. Sealing material:

It can be as sealing ring in the equipment, such as centrifugal pump, hydraulic turbine , etc.

5. Anticorrosion material:

Widely used in petroleum, chemical, hydrometallurgy departments.

6. Protection materials

Insulation, high temperature resistant, radiation

Specifications:

Technical date sheet:

Graphite rods are often used for following:

1. Refractory material:

Widely used in the metallurgical industry.

2. Conducting material:

In the electronics industry, widely used for graphite electrode, brush,, etc

3. Wear-resisting material and lubricant:

Use graphite as wear-resisting and lubrication materials, can be 100m/s speed sliding in - 200 ~ 2000 °C temperature range, no or less lubricanting oil.

4. Sealing material:

It can be as sealing ring in the equipment, such as centrifugal pump, hydraulic turbine , etc.

5. Anticorrosion material:

Widely used in petroleum, chemical, hydrometallurgy departments.

6. Protection materials

Insulation, high temperature resistant, radiation

Specifications:

| Diameter | length (mm) | around weight kgs |

| Φ20 | 1700 | 1 |

| Φ25 | 1700 | 1.5 |

| 1900 | 1.68 | |

| 2200 | 1.95 | |

| 2250 | 1.98 | |

| Φ30 | 1700 | 2 |

| 1900 | 2.24 | |

| 2200 | 2.59 | |

| Φ35w | 1700 | 2.85 |

| 1900 | 3.2 | |

| 2100 | 3.52 | |

| 2200 | 3.68 | |

| Φ40 | 1700 | 3.5 |

| 1900 | 4 | |

| 2100 | 4.32 | |

| 2200 | 4.63 | |

| 2400 | 5.05 | |

| 2270 | 4.7 | |

| Φ45 | 2250 | 5.21 |

| Φ50 | 1700 | 5.5 |

| 1920 | 6.3 | |

| 2100 | 6.8 | |

| 2200 | 7.12 | |

| 2500 | 8 | |

| Φ60 | 1400 | 6.5 |

| 1700 | 7.9 | |

| 1300 | 6.04 | |

| Φ63 | 2000 | 8.7 |

| Φ70 | 2100 | 5.68 |

| 2250 | 5.5 | |

| 2500 | 6.3 | |

| Φ72 | 2250 | 15.7 |

| 2470 | 17 | |

| Φ75 | 2250 | 16.4 |

| Specifications | Unit | Value |

| Bulk Density | g/cm3 | 1.65-1.80 |

| Compressive Strength * | MPa | 20-55 |

| Bending Strength * | MPa | 10-30 |

| Elastic Modulus * | GPa | 9-21 |

| Specific Resistance * | μ Ω·m | 5.0-15.0 |

| Ash | % | 0.05-0.5 |

Want to Know more details about this product